Tube Notcher - Super Booster 2000

I designed the whole idea of the construction already 5 years ago, since then I have been trying to make modifications all the time to make it the best. The latest version is improved by, among other things

hardened shaft (the same as used for cylinders in construction machines), a special tip for quick change of holesaws, a graduation angle for easy and quick setting of the device for the job, pins (so that the pressure of the material always holds in place), angle lock for repeat cuts, and several other improvements that significantly increase the comfort of work. However, they also increased the price 😉. My goal was to create a product with the best possible parameters and at an affordable price for everyone. At the beginning I assumed selling the set a bit cheaper, but I came to the conclusion that increasing the quality will be a good decision.

The set includes:

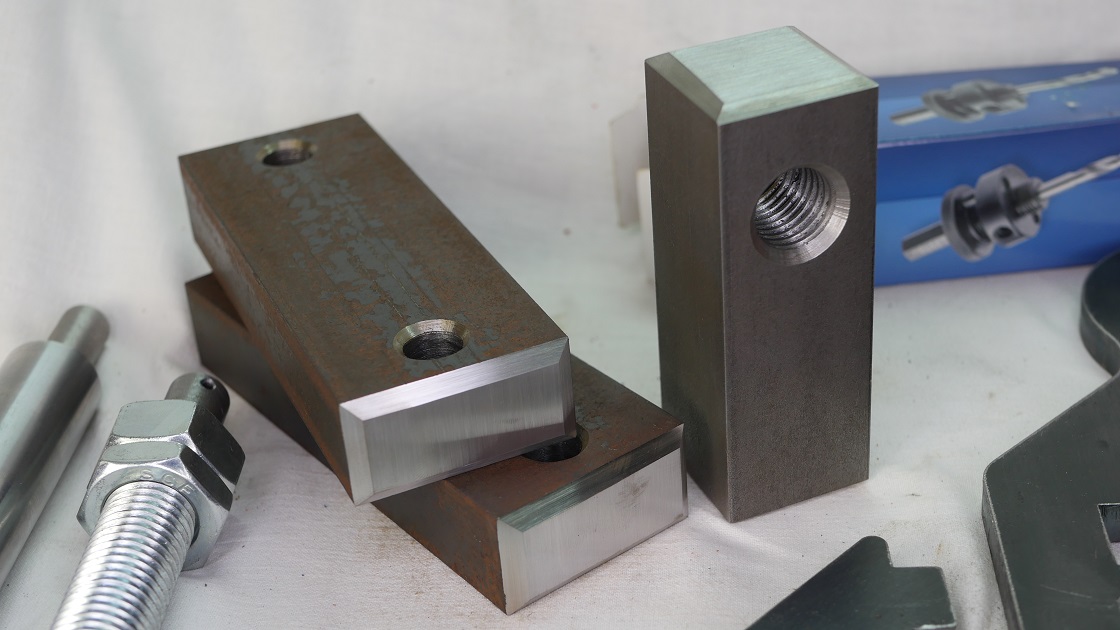

11x sheets cut out by laser (prepared for welding by means of edge processing, holes, threading, etc.; accuracy of cut out elements is 0.03 MM, cut out on one of the best available laser sources in Poland)

2x bearing stand

1x post with M20

thread1x set of screws (as shown in the pictures, total 18 elements)

1x pin - to pin

1x turned material pressure M20

1x quick change hole bit (shaft-mounted)

1x turned hardened shaft

2x MGK bearing

1x sliding washer between sheets

2x worm-type screw to fold the shaft

1x engraved angle with logo - currently free (purchase price 25 PLN)

1x rivet for accurate reading of the current angle

1x electronic assembly instructions (pictures)

1x Allen pipe wrench (not pictured)

1x angle lock, for repeatable cuts

Complete set, ready for assembly. It takes about 30 minutes to assemble the set. Below is a list with the necessary tools needed for construction. ;)

As you can see, in the picture next to it, the place where you have to weld a threaded pole

was pressed through a laser engraver with an accuracy of a hundredth of a millimetre, which, combined with a groove fit, guarantees pleasant work without surprises 😉.

I designed the whole folding set in such a way as to make it easy to assemble, so that even a novice DIY enthusiast wouldn't have any problems with it, and the whole folding process was more like fun than work. 😉

The specially calibrated angle bar will be your best friend at work, as it will save you a lot of time and I will make sure the cuts are repeatable 😉.

In the set, I make every effort even where seemingly they are not required, the ideal example of this are ground edges of, among others, bearing stands or post with M20 thread, it is only a stylistic procedure that does not affect the work of the attachment.

Thanks to the use of beans for fixing the bearings, we have the possibility of very quick adjustment, and most importantly, infinitely variable. This is especially important when we want to change the size of a pipe or profile frequently.

Combining the fight with the pinhole was the biggest challenge for me. Initially, I threaded the bar itself, but this connection did not work with larger holesaws. I decided not to balance the open door and used the original adapter to fix the holesaws. It has special pins that absorb all the energy to prevent damage to the thread.

| Parameter | Value |

|---|---|

| Minimum diameter of pipe to be fixed | 27mm |

| Maximum diameter of the fitted pipe | 91mm |

| Minimum length of pipe to be fixed | 240mm |

| Possibility to mount holesaws in the range | 29-95mm |

| Ability to mount holesaws | 14-30mm (additional adapter required + €9) |

| Portable range of angles | 0-60° |

| Grade of steel | S355 |

| Bolt grade/hardness | 8.8 |

| Weight | 20kg |

| Color | Stainless steel, no paint coating |

| Dimensions of packaging for shipping | 35×25×15 cm |

My package of the tubing notcher has arrived. I thank you for shipping it to me as it arrived in good shape and the box was not damaged. I will get this welded together and painted similar to the way you have shown yours. Thank you again.

Good morning Patryk, Thank you for sending me the parcel. Received it last week and was very well packed and presented. The parts look very professional, especially the spindle for the drillbit looks super!! Ik can't wait to put it all together and start working with it but right now it's a little bit cold in the shed. I'm sure it's the same in Poland? Once again thank you and I'll keep you posted when i have put it together. Cheers. Ben

Compre la maquina a patryk y me llego en 5 dias desde polonia a españa, un placer tratar con Patryk

Wirklich ein sehr gutes Produkt der Shop ist absolut vertrauenswürdig ich habe es vor Weihnachten bestellt im neuen Jahr bekommen jetzt vor kurzem zusammengeschweißt und es ist alles 100% für den Preis vor allen Dingen immer netter Kontakt das Puzzle ist echt sehr genau gearbeitet ein Traum

English:

Really a very good product the shop is absolutely trustworthy I ordered it before Christmas in the new year now got welded together recently and it's all 100% for the price above all always nice contact the puzzle is really very accurate a dream

Panie Patryku ostatnio złożyłem zakupiona wykrawarke i muszę przyznać robi robotę fajnie się na niej pracuje, jestem naprawde zadowolony. Pozdrawiam

Also want to share your own buying experience?

Currently it is not possible to add feedback directly via the site, so if you would like to add feedback please send it to opinions@trajder.com and I will add it manually to the site. Thanks in advance for your feedback, it means a lot to me! ;)

Presentation of possibilities

In the machine we can punch pipes from 28 to 91mm, an example of which is the photo next to it ;)

example of a 91mm pipe connection at right angles.

Below I present to you a film showing the capabilities of my razor. The film has not been updated yet and shows the old model of the razor. The newer version has been improved, but the principle of work and editing is the same so I took the liberty of temporarily adding the film 😉.